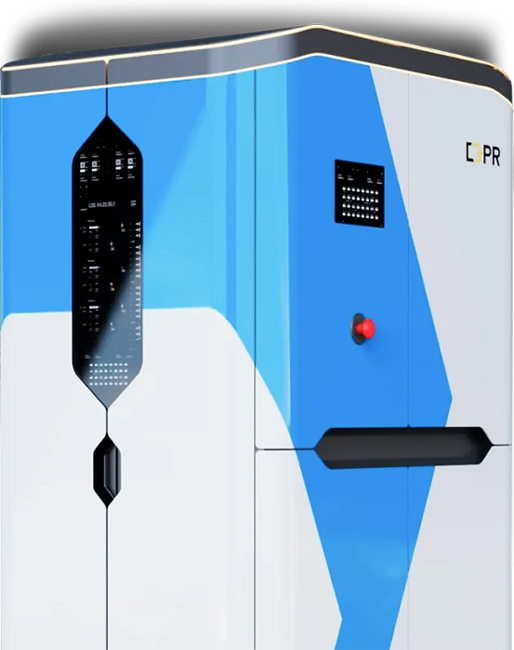

ACM 4.0

Measurement and monitoring of key coolant parameters

Automatic maintanance of the optimal coolant level in the tank

The option to connect a group of machines to the station

Equipment protection from coolant negative effects

Implementation Benefits

The use of the automatic coolant monitoring station ACM provides maximum coolant efficiency for stable and high-performance processing, machine protection and personnel safety

Coolant replacement interval increases by 1.5-2 times

Maintaining favorable working conditions and production culture

Preventing the coolant impact on machine units

Coolant maintenance is performed automatically

Made in Russia

A patented invention by CEPR Group.

- A unique Russian invention that surpasses the closest analogues in range of parameters

- The high value of the invention is confirmed by support from the Innovation Promotion Fund

- Implementing innovative solutions in the automation of coolant maintenance with Russian components

- Developed and manufactured in Russia with over 85% Russian components

Creation history

-

Establishment

The CEPR Group is established as an expert centre in supply, maintenance and repair of complex units of metalworking equipment

-

Development of ACM

A decision was made to develop ACM coolant. The accumulated experience in the field of equipment repair confirms the relationship between the quality of coolant service and the frequency of breakdowns of machine components

-

«Metalloobrabotka 2021»

A station prototype is presented. Active interest and pre-orders prove the solution's relevance

-

Pilot operation

Start of the ACM prototype testing in the production conditions of an industrial complex in Novosibirsk

-

Industrial Design

Serial model appearance and case ergonomics development with leading design bureau involvement in the field of industrial design, the Formlab company.

-

Patent Application

Applied for a patent for the invention of coolant ACM

-

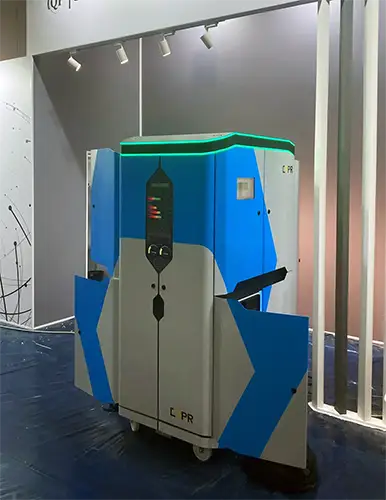

«Metalloobrabotka 2022»

A modification of ACM's serial sample is presented

-

«Innoprom 2022»

Coolant ACM is presented under the the stand of the machine-tool holding JSC Mekhanika, Rostec State Corporation

-

Grant received

The application for a grant for the implementation of an innovative project for the production of coolant ACM in order to increase the productivity of CNC machines is approved

-

Completion of the OPE

The results of the prototype testing in the production conditions of an industrial enterprise in Novosibirsk confirm the high technical and economic efficiency of coolant ACM

-

Patent received

The patent for the invention of ACM is was been received

-

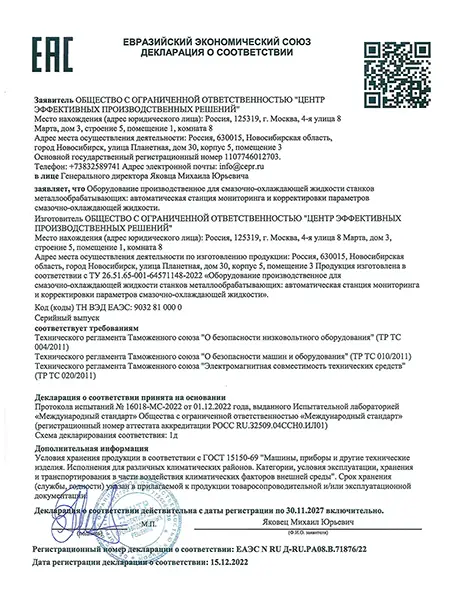

Declaration received

The declaration of compliance of products to the requirements of the technical regulations of the EAEU is was been received

-

First deliveries

The first four stations shipped to St. Petersburg and to Miass

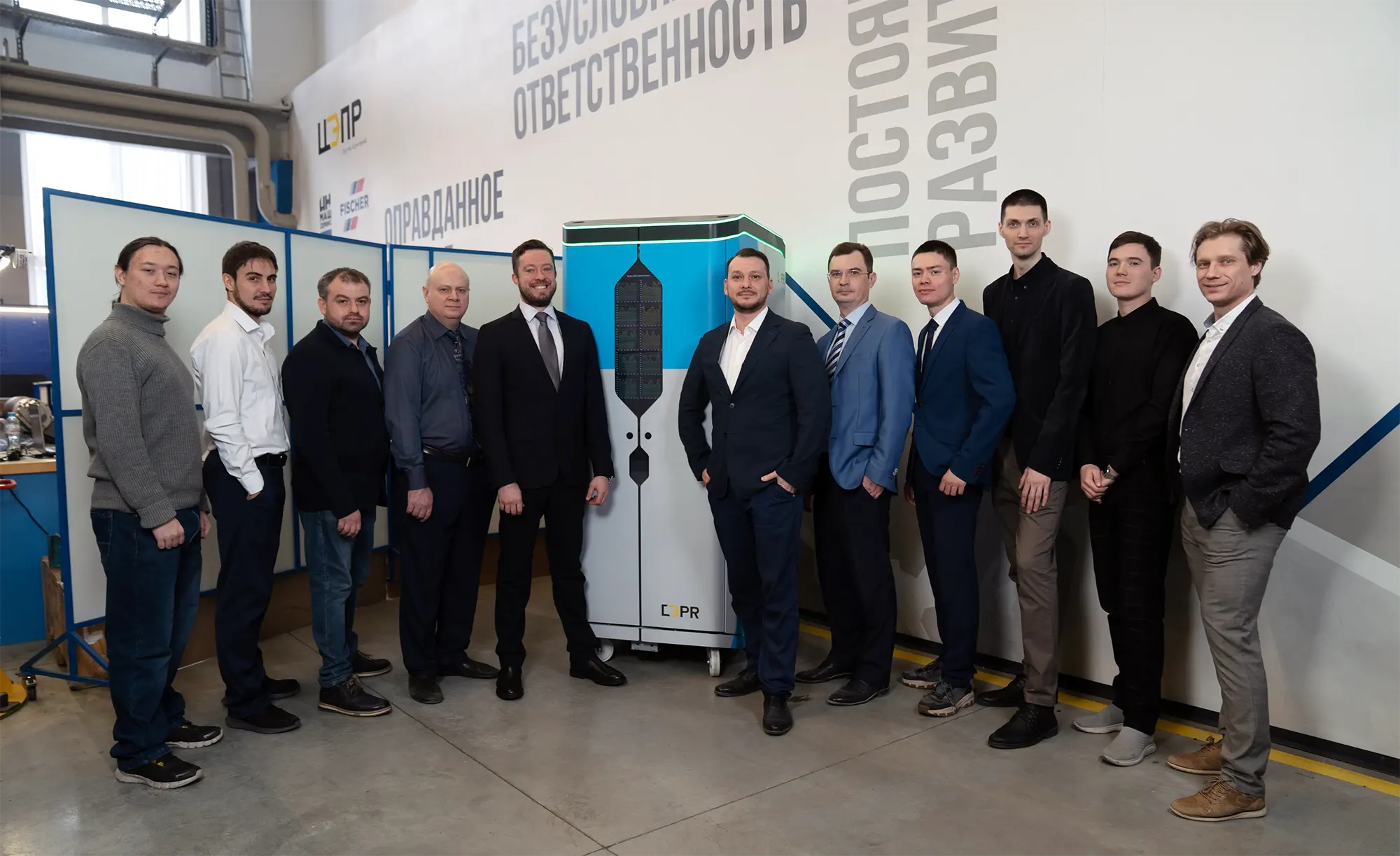

Our Team

We are a close-knit team of ambitious engineers with higher technical academic background, experienced managers and young specialists in related fields. Our professional skills allow us to create unique solutions that have no analogues in the world.

Success stories

Industrial enterprise, Novosibirsk

During the testing period, imported emulsion was replaced with Russian-made coolant. It was found that the use of the automatic coolant monitoring station ACM makes it possible to maintain the performance characteristics of the Russian coolant at the level of the original imported analogue, which makes the import substitution procedure harmless to the production process.

Industrial enterprise, Miass

Previously, when servicing the coolant, the customer faced a strong influence of the human factor, e.g. errors in the emulsion preparation, untimely service, increased concentrate consumption. After the automatic coolant monitoring station ACM installation, the emulsion is prepared automatically, the concentration and level of coolant in the tank are in the optimal range, the coolant concentrate consumption has decreased by 20%.

Industrial enterprise, St. Petersburg

In a rapidly developing production environment, the customer needed a solution to automate the coolant maintenance procedure and a reliable reporting system. As a result of the coolant ACM installation, machines are serviced offline, and the up-to-date data on key coolant indicators is available 24/7.

Statistics

48,000 liters per day — the emulsion volume serviced by ACM

1,450 hours — reduce machine downtime for coolant changes

79 — the total number of machines connected to ACM

1,500,000 rubles per month are saved on coolant maintenance on machines connected to ACM

Scientific articles

Contacts

Contact us